High school days make me really tired:(

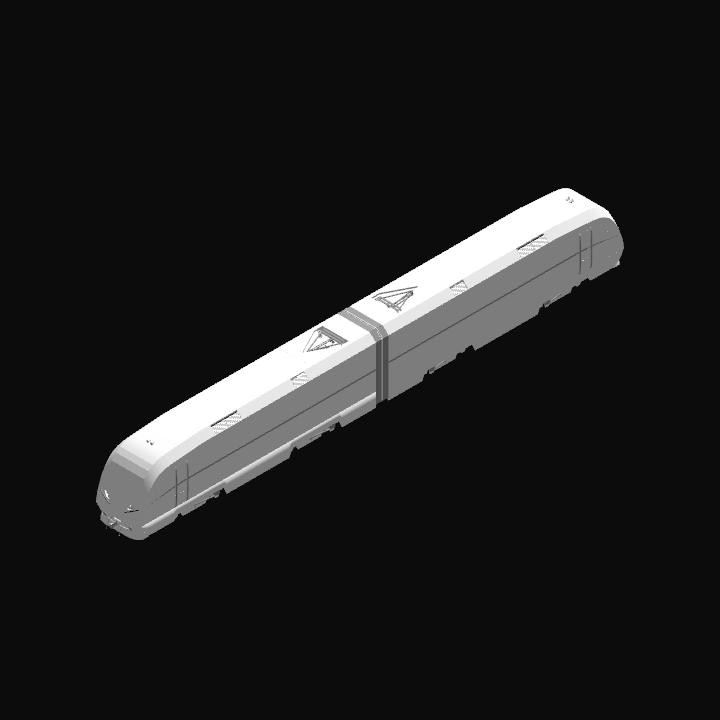

about HXD1G

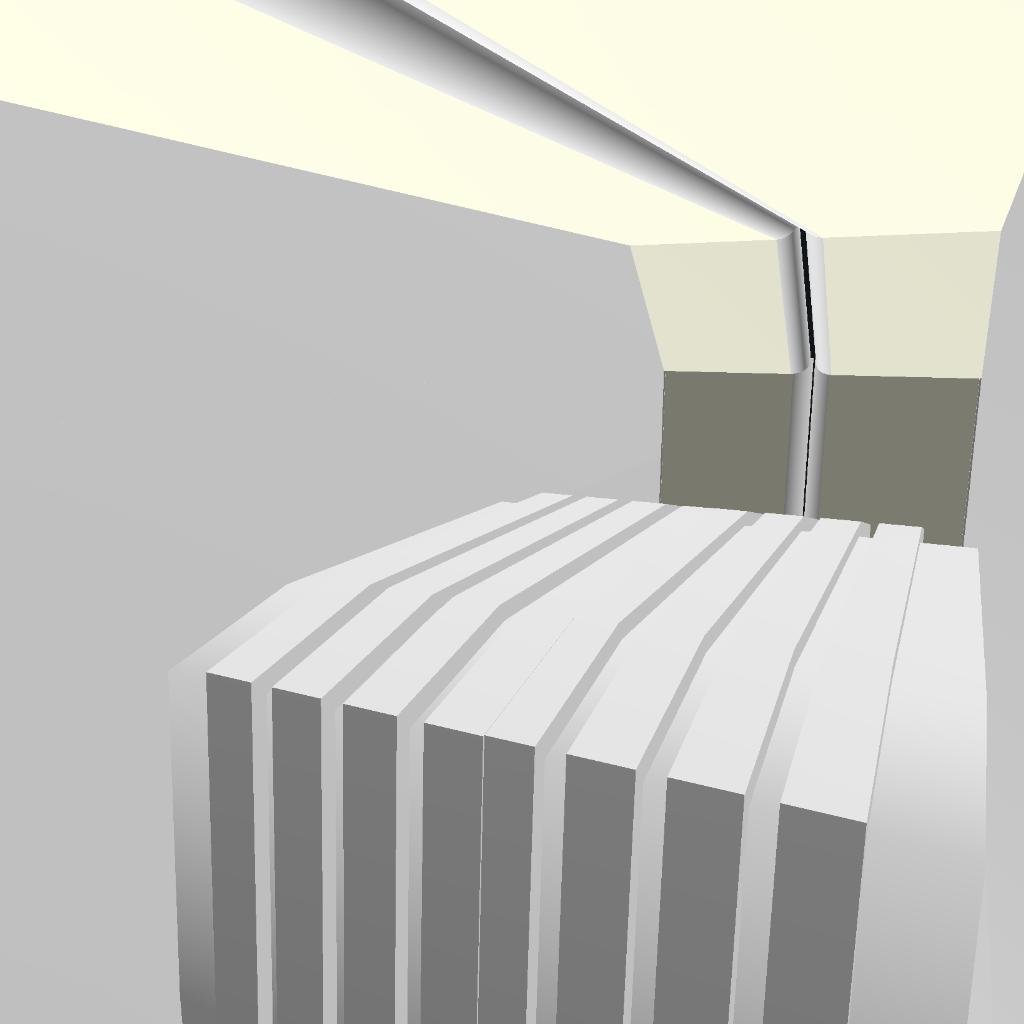

The HXD1G AC drive electric locomotive is a new generation 200km/h eight axle high-power electric locomotive developed by Zhuzhou Factory in 2015. Power 11200kW, maximum speed 210km/h.

The HXD1G locomotive was manufactured in September 2015 and is the most powerful AC high-speed electric locomotive in China. The locomotive is developed based on the existing HXD1 series locomotives, and through lightweight design and technological innovation, it can meet the traction requirements of high-speed and conventional passenger cars. The locomotive can pull 18 car passenger trains to run at a speed of 210km/h. The HXD1G locomotive has a curb weight of 2X78t, axle weight of 19.5t, and axle type 2 (B0-B0). The maximum test speed is 231km/h, the maximum operating speed is 210km/h, and the sustained speed is 95km/h. Continuous power of 11200kW, starting traction force of 480kN, continuous traction force of 424kN. Through a minimum curve radius of 125m.

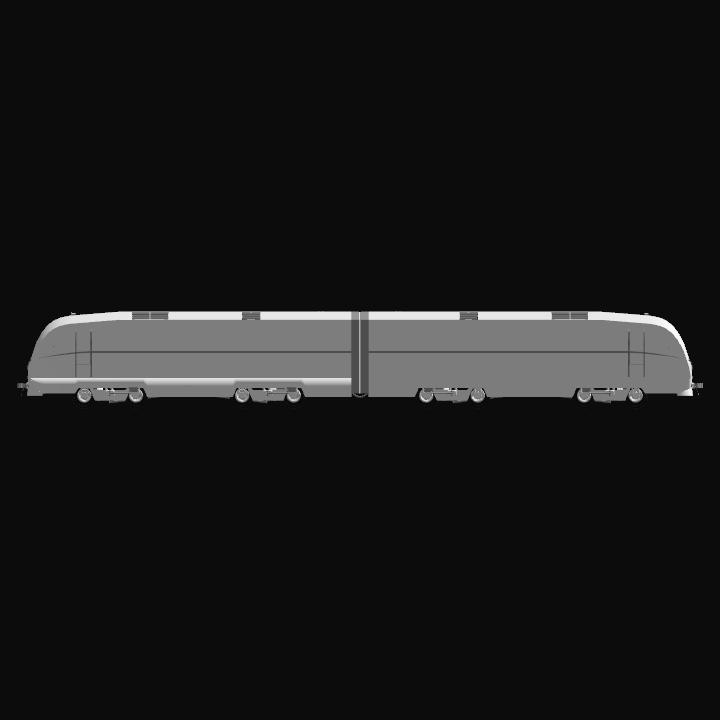

The HXD1G locomotive consists of two locomotives and is a lightweight overall load-bearing structure body. The driver's cab is located on both sides, and the central mechanical room is designed with a central through corridor. The equipment is arranged in a diagonal symmetrical manner. The mechanical room is equipped with traction fans, traction converters, main cooling towers, auxiliary filtering cabinets, low-voltage electrical cabinets, 6A system cabinets, battery and control power cabinets, third-party equipment cabinets, brake cabinets, compressors and dryers, toilets, tool cabinets, train power supply cabinets, grid side cabinets, etc.

The equipment layout in the driver's cab is divided into five parts: control panel equipment, front wall equipment, rear wall equipment, side wall equipment, and top equipment.

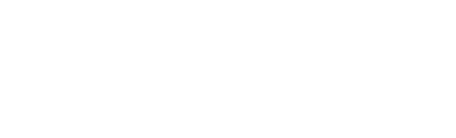

The HXD1G locomotive consists of two cars, A and B, each equipped with a complete independent and identical electric transmission system. The two workshop network side circuits are connected through a high-voltage jumper on the roof. Adopting high-power IGBT water-cooled inverter and horizontal traction transformer. Each locomotive's electric transmission system consists of one traction transformer, one traction inverter, and four traction motors. The secondary side of the traction transformer has 4 traction windings and 2 train power supply windings. Each traction inverter supplies power to 1 asynchronous traction motor to achieve traction motor shaft control. The traction inverter adopts a modular design based on 6.5kV IGBT converter components and forced water circulation cooling technology.

The train is powered by two independent and identical lines, each with a capacity of 400kW. When one line fails, the other can maintain power supply.

The bogie frame adopts a 16MnDR low-alloy steel plate box welded Japanese shaped structure. The suspension system consists of steel springs, vertical shock absorbers, and rubber pads. The secondary suspension consists of steel springs, vertical shock absorbers, lateral shock absorbers, anti snake shock absorbers, etc.

The traction motor adopts an opposed arrangement. The drive system adopts an elastic frame suspension structure, a hollow shaft six link transmission device, a single-sided cylindrical spur gear transmission, and a load-bearing cast aluminum alloy main gearbox. The large gear transmission bearing adopts cylindrical roller bearings, and the axle box bearing adopts integral maintenance free cylindrical roller bearings. Adopting integral wheels and JM3 wear type tread. The wheelset adopts axle box arm positioning. Adopting a push-pull low position single traction rod. The gear ratio is 89/23.

The HXD1G locomotive adopts two types of brakes, CCB-II and DK-2. Both models have compatible electrical interfaces. The brake control system has functions such as automatic braking, individual braking, backup braking, emergency braking, parking braking, and flameless return,

The 0001 car adopts CCB-II type brake, which is designed by Knorr Bremse and is a network-based electric air brake. The brake is composed of electronic brake valve, central processing module, brake display screen relay module, electric pneumatic control unit, and backup brake module.

The 0002 car adopts the DK-2 brake, which was designed and developed by Zhuzhou Factory. It has information technology functions such as microcomputer simulation control, network communication, and intelligent fault diagnosis. It consists of a brake controller, backup brake valve, brake display screen, and brake cabinet.

The locomotive basic braking device adopts disc brakes, and the brake caliper unit is divided into two types: with parking brake and without parking brake. The brake caliper unit is suspended on the bogie frame in a three-point floating manner. The brake disc is made of integral cast steel or forged steel, and the brake pads are made of standard dovetail powder metallurgy brake pads. Adopting regenerative braking with a braking force of 305kN.

Adopting the No.15 small gap coupler (103 type) and 103-2 type buffer. A semi permanent coupler 106 type buffer device is used between the two vehicles. There is one train pipe, two air supply pipes, and two averaging pipes at the locomotive end.

about the controls

AG1/AG2 choose sides AG 3 for power slider1 for run. AG10 for doors

enjoy!

IF you like it,plz leave your comment and give me a support!

11 Comments

- Log in to leave a comment

-

-

27.1k Zenithspeed7 months ago

awesome

i really like twin-section locomotives (my favourites are the Skoda ChS8 and the DF11G), so seeing this made me happy -

-

9,162 JedediahTheDrooman7 months ago

@fastplanesforjunofun sped up after the turn to avoid this problem:)

-

690 OrbitalOrigins7 months ago

@JedediahTheDrooman Sorry if I’m bugging you but the train just randomly started slowing down and the wheels are off the ground

-

-

9,162 JedediahTheDrooman7 months ago

@fastplanesforjunofun i test for second time so i think it might be your device’s problem:(

-

-

-

690 OrbitalOrigins7 months ago

I just wish it didn’t fall off on the turn and I was going as slow as possible

@Zenithspeed they looks really cool,aren’t they?