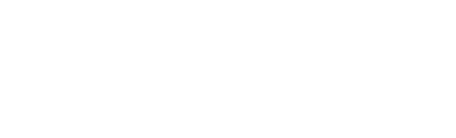

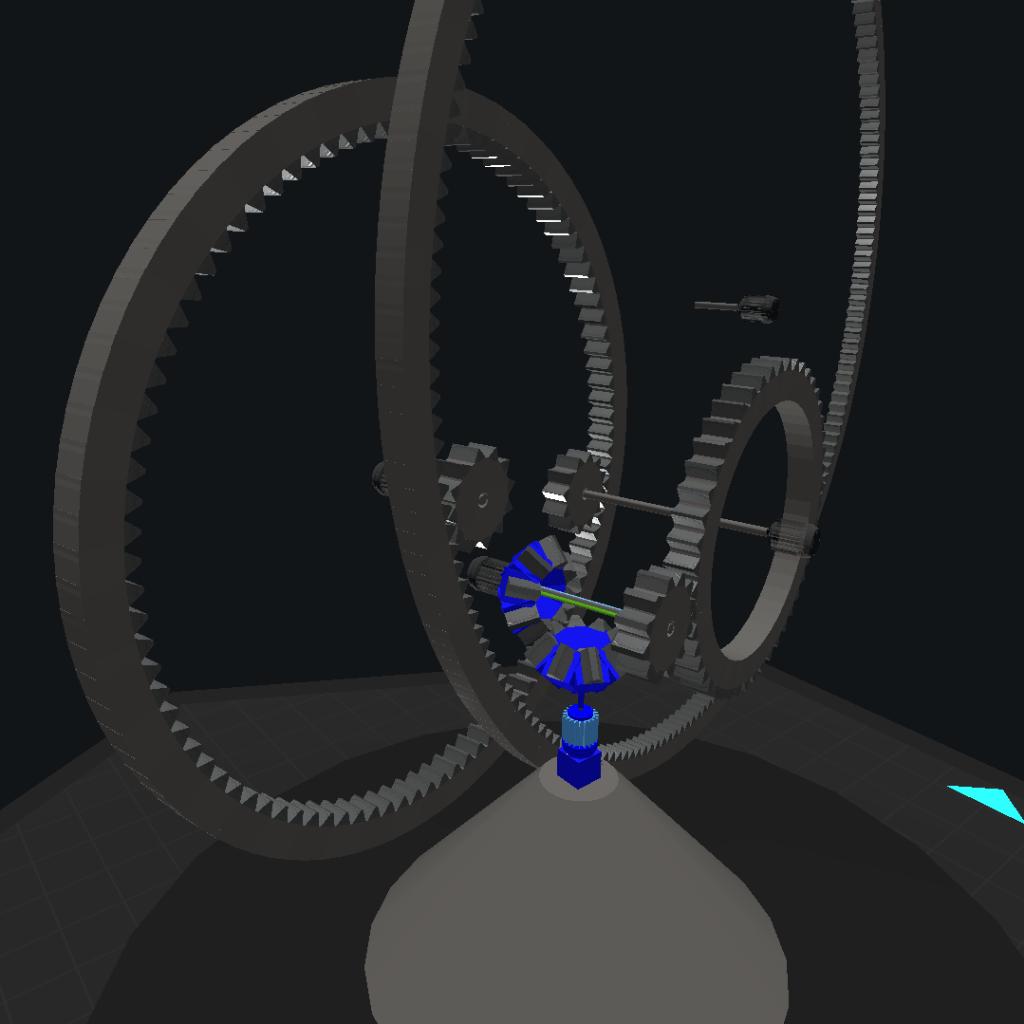

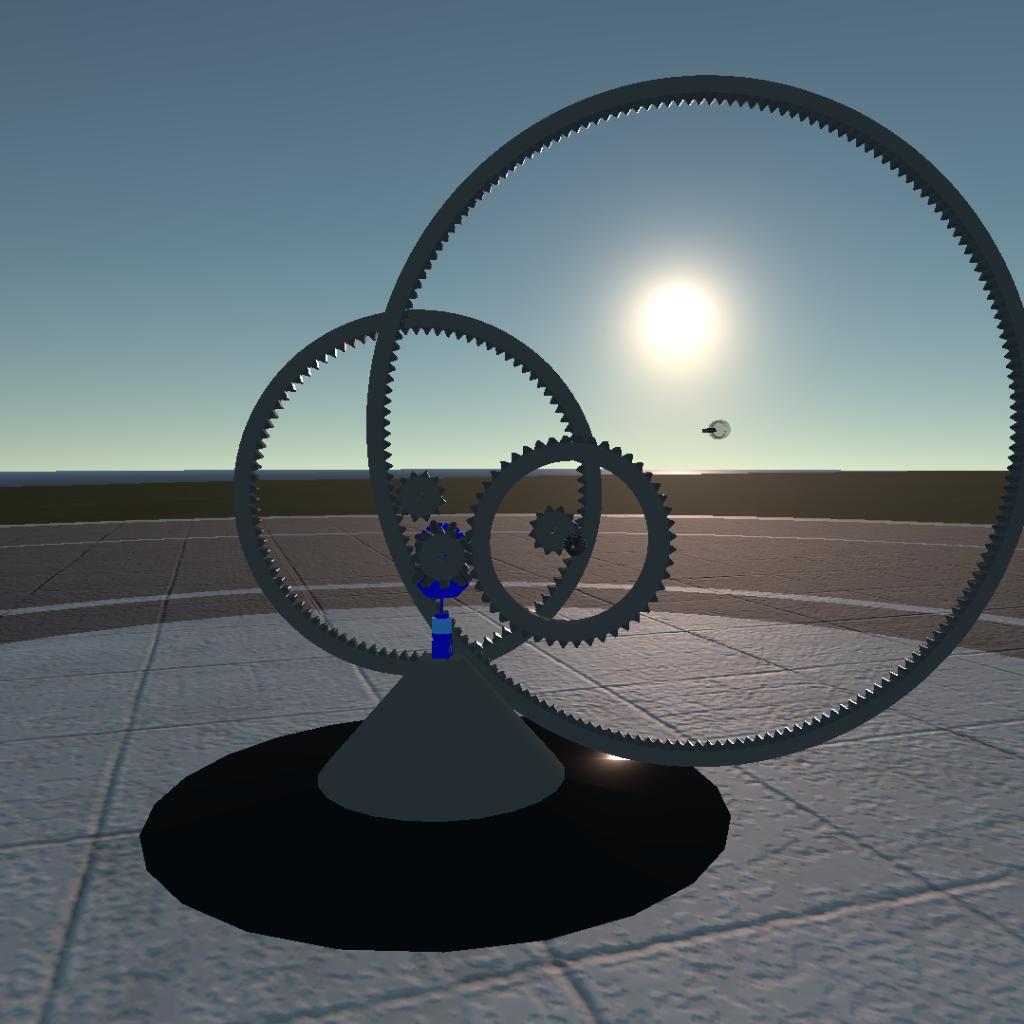

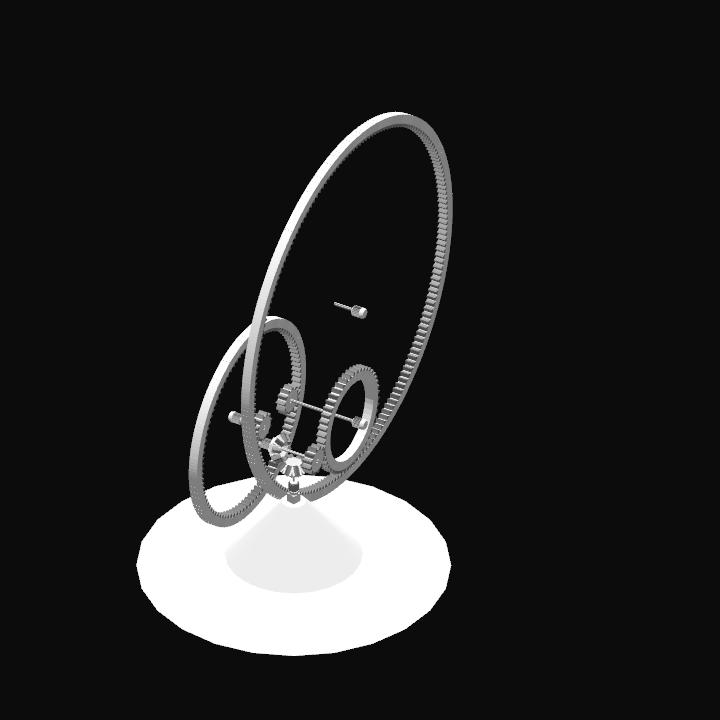

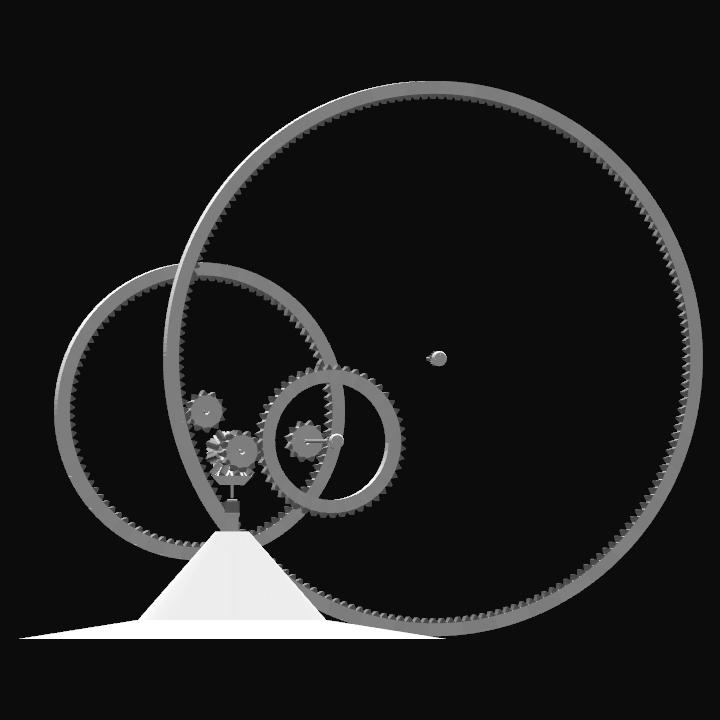

This is one of the original models from some of the first gears I made. It has:

8 Tooth bevel gear to change from vertical motor to horizontal output

12 tooth to 24 tooth step

24 tooth to 48 tooth step

48 to 96 tooth step on the final.

Outdise 12 tooth and inside 12 tooth are different gears.

12 points are drive gears for each set (except the first which go 8 point to 12 point)

42 (2/3) : 1 final drive

Each tooth weighs about 9kg, bringing the gear weight the motor moves to around 3,000 kg alone. Enough weight that if you 0 the slider it will free wheel a bit.

The 24 tooth is off (too much gear spacing, too large of a diameter) but works well because of the extra weight to keep in sync like a flywheel.

1 Comment

6 Upvotes

Log in in to upvote this post.

Check out the power lift test version of the 65,536:1, this thing has some torque 🤯 that one torques so hard it tears through parts and breaks itself when it get stuck. I've got a lot of uses for that torque output plus a few other ideas for electric motors and drives using gearboxes @Starborn